Global OLED Equipment Manufacturers Drive Innovation in Display

Organic Light-Emitting Diode (OLED) technology, recognized as the next-generation flat-panel display solution following CRT, PDP, and LCD, continues to revolutionize the electronics industry with its superior performance and versatility. Leveraging organic semiconductor materials that emit light under electric fields, OLED offers a fully solid-state design combining the advantages of CRT’s high contrast and LCD’s slim profile, while eliminating legacy drawbacks.

OLED Structure and Functionality

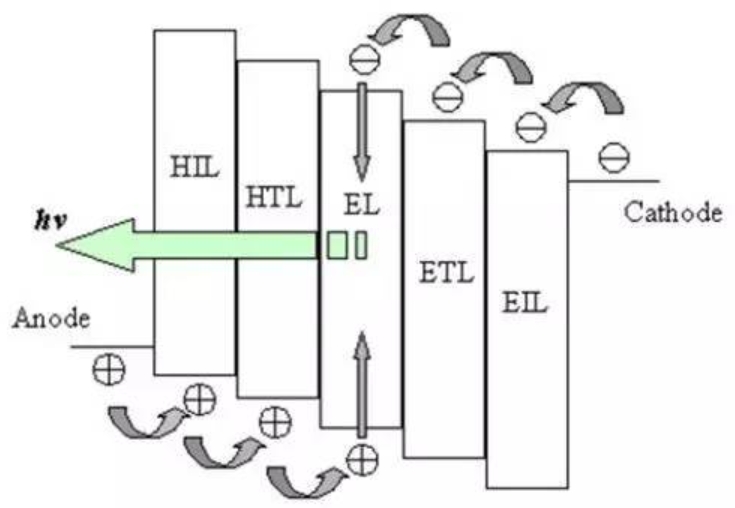

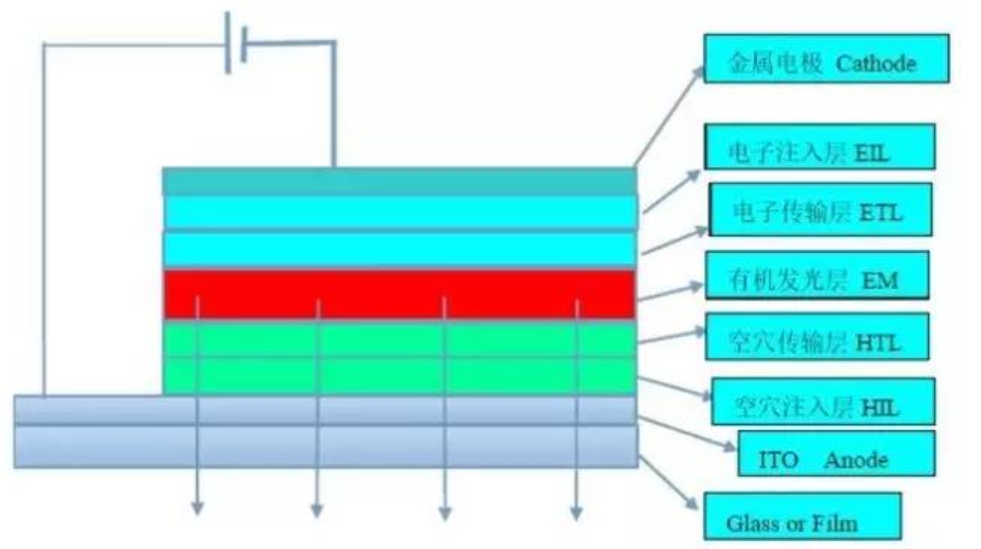

A typical OLED device comprises multiple functional layers, including the anode, hole injection layer (HIL), hole transport layer (HTL), organic emissive layer (EL), electron transport layer (ETL), electron injection layer (EIL), and cathode. These layers are engineered to create a “staircase” energy-level structure (Fig. 1), facilitating efficient recombination of holes and electrons within the emissive layer to produce light. Advanced doping techniques further optimize energy levels (Tables 1-2), enhancing device efficiency and lifespan.

OLED production relies on highly specialized equipment tailored for both passive matrix (PM-OLED) and active matrix (AM-OLED) technologies. Critical systems include:

PM-OLED: Organic evaporation and encapsulation tools.

AM-OLED: Deposition systems: Sputtering platforms, plasma-enhanced chemical vapor deposition (PECVD), and vacuum thermal evaporation (VTE) for thin-film transistor (TFT) layers.

Patterning tools: Coaters, exposure machines, and dry/wet etchers for TFT circuit fabrication.

Annealing systems: Furnaces, gas pipelines, and laser annealing equipment.

Testing & repair: TFT electrical testers, OLED optical analyzers, and laser repair machines.

The global OLED equipment supply chain is dominated by specialized manufacturers in South Korea and Japan, home to industry pioneers driving innovation in precision deposition, patterning, and testing technologies. Leading companies have cemented their positions through breakthroughs in high-throughput manufacturing and yield optimization. It is critical for mass-producing OLED panels used in smartphones, TVs, and wearable devices.

Post time: Apr-10-2025