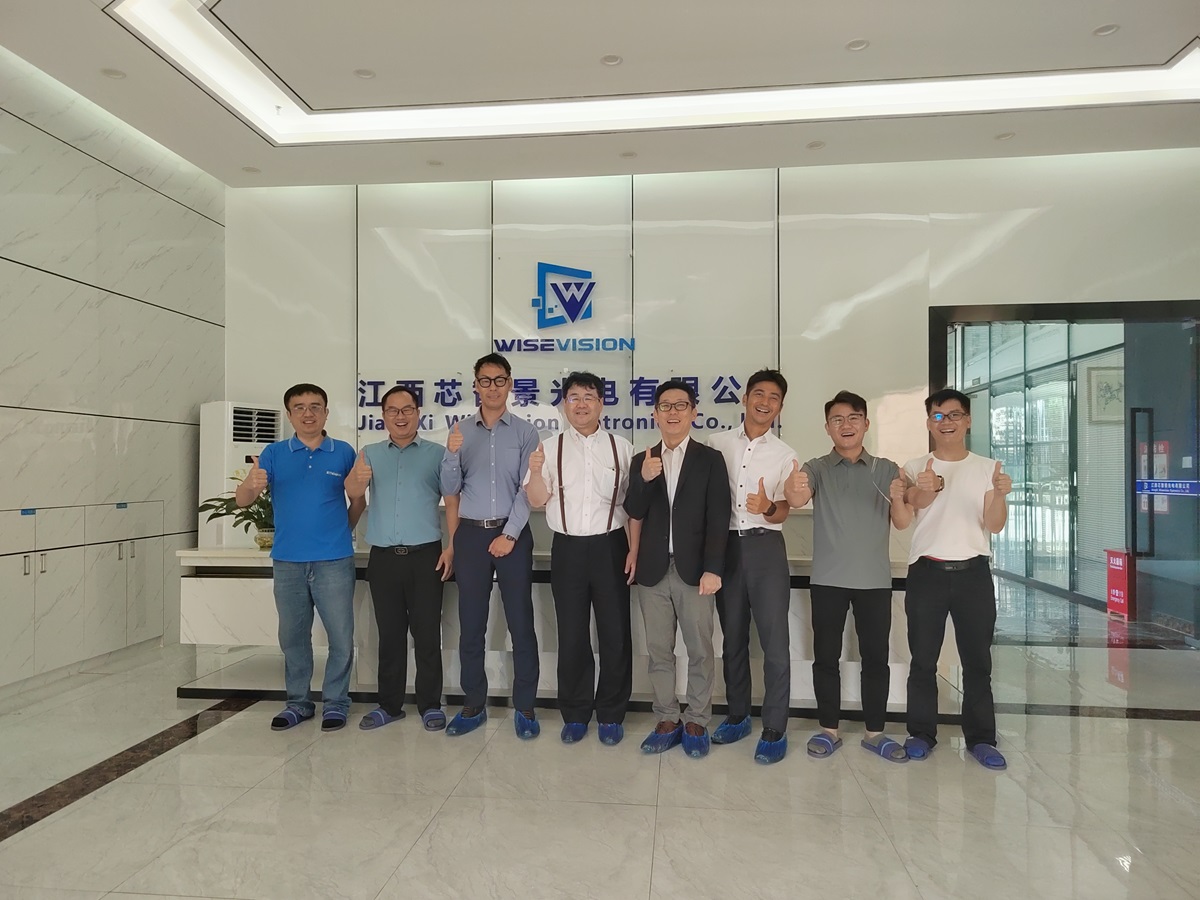

On July 11, 2024, Jiangxi Wisevision Optronics Co., Ltd. welcomed Mr. Zheng Yunpeng and his team from MAP Electronics in Japan, as well as Mr. Takashi Izumiki, the head of the Quality Management Department at OPTEX in Japan, to visit, evaluate, and exchange ideas. The purpose of this visit and evaluation is to assess our company's product production process control, factory environment, management system, and overall factory operation.

During the on-site review, the customer gained a comprehensive understanding and evaluation of our warehouse layout, warehouse management, production process control, production site planning, and the operation of the ISO system.

The detailed evaluation process and summary of the guests' visit are as follows:

According to the process flow of the product, the customer first came to our IQC and warehouse. The customer conducted a detailed review of the inspection facilities and standards for IQC inspection, and then had a detailed understanding of the on-site layout, material classification and placement planning, various material protection measures, warehouse environment management, material entry and exit management, and material storage management of our warehouse. After on-site visits and inspections at IQC and the warehouse, the customer gave high praise to our company's planning, labeling, and daily maintenance of these two areas, truly achieving unified material labels, clear labeling, and implementation of systems in every detail.

Secondly, the guests visited and evaluated our OLED and TFT-LCD module production workshops, conducting a detailed review of the product manufacturing process, workshop planning and labeling, personnel working status and atmosphere, equipment operation and maintenance, product protection, and material control. The customer fully affirmed the manufacturing process of the product, from cutting to finished product warehousing, the operation instructions for each position, the execution of operation methods, on-site material and position identification, the full automation of production equipment, and online quality monitoring measures. The standard of SOP is highly consistent with the actual operation personnel, the automation level of product manufacturing reaches over 90%, the clarity and operability of on-site identification, and the effectiveness and traceability of product quality monitoring and recording are high.

In addition, the customer also conducted a detailed review of our company's ISO system documents and their operation. Give full recognition to the integrity of our company's documents, the consistency between document content and operation, and the management and maintenance of documents. They believe that our company has achieved high standards in the operation of the ISO system within the industry.

Throughout the entire visit, the visitors were very satisfied with the overall planning of our factory and highly praised our management team, corporate culture, and other aspects. They believe that Jiangxi Wisevision Optronics Co., Ltd. has demonstrated refined and efficient management in every aspect, demonstrating the company's comprehensive strength and management level.

This visit to the factory is a comprehensive inspection and praise of Jiangxi Wisevision Optronics Co., Ltd. We will continue to uphold the attitude of striving for excellence, continuously improve our management level and production efficiency, and provide customers with higher quality OLED and TFT-LCD products and services.

Post time: Aug-17-2024